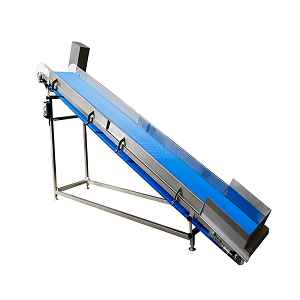

Vegetable Conveyor

Vegetable Conveyor

Blog Article

Vegetable conveyor is a conveying system designed specifically for the food processing industry, especially for transporting vegetables cut into shreds, slices or segments. The equipment is designed to improve the efficiency of food handling and processing by providing a continuous flow for the transportation of vegetable products. It is particularly suitable for applications where cleanliness, food safety and efficiency are critical.

Usage: Used for lifting and conveying vegetables that are cut into threads, pieces, and segments.

Features

Food Grade 304 Stainless Steel Construction: The vegetable conveyor is primarily made of high-quality food grade 304 stainless steel, ensuring the durability, corrosion resistance, and sanitation required for food handling environments. This material choice makes it easy to maintain and prevents contamination during conveying.

Easy-to-clean design: The conveyor's surface design is smooth and easy to clean. The frame and belt can be quickly disassembled, making manual cleaning more efficient and reducing downtime between production cycles.

Food Grade Conveyor Belt: The conveyor belt itself is made of food grade materials, ensuring it is safe for direct contact with food. This material helps prevent contamination and supports food safety regulations.

Adjustable Conveyor Belt Speed: The speed of the conveyor belt can be adjusted to the specific requirements of the production line. This flexibility can optimize processing speeds based on the type of vegetable and stage of processing.

Technical Parameters:

Overall dimensions: 2860×850×1500mm

Voltage: 380V

Power: 0.37kW

Production: 800-1000kg/h

Customization: customizable

Benefits

Sanitation and Safety: The use of food-grade materials for both the frame and conveyor belt ensures the system meets strict food safety standards. The easy-to-clean design helps maintain hygiene, reduces the risk of contamination and improves overall food safety.

Durability and Lifespan: The use of stainless steel construction ensures that the conveyor belt is durable and corrosion-resistant, even in challenging environments such as wet or humid areas common in food processing plants.

Operational Efficiency: The adjustable conveyor speed can be tailored to the needs of specific applications, helping to optimize processing efficiency and reduce bottlenecks in the production line.

Cost-Effective Maintenance: The ability to quickly disassemble and clean the conveyor system reduces downtime for maintenance and cleaning, ensuring that production remains continuous and labor costs are minimized.

Specific Applications

Vegetable conveyor belts are used in various stages of vegetable processing, including:

Cutting and Shredding Lines: After the vegetables are cut into shreds, slices or segments, the conveyor belt transports them to further processing stations, such as washing, packaging or seasoning.

Sorting and Inspection Stations: These conveyors can be integrated into sorting lines, where vegetables are sorted by size or quality before moving on to the next stage of production.

Packaging: After the vegetables are processed and prepared, the conveyor system moves them to the packing station, ready for distribution.

Precooking and Freezing: For vegetables that need to be blanched, precooked, or frozen, the conveyor system plays a vital role in moving them to these steps.

Precautions

Regular Cleaning: It is essential to clean the conveyor system regularly, especially after processing different types of vegetables, to prevent cross contamination.

Belt Tension Maintenance: Make sure the conveyor belt is properly tensioned to avoid slipping or uneven transportation, which can disrupt the production process.

Adjust Speed Carefully: While adjustable speed is a key feature, it is essential to adjust the conveyor belt speed according to specific processing requirements. Too high a speed may cause spillage or poor product handling, while too low a speed will result in inefficiency.

Check for Damage: Regularly check the conveyor belt and other parts of the conveyor system for wear. Replace damaged parts promptly to avoid interruptions in the processing line.

In conclusion, the vegetable conveyor belt is an important equipment for any food processing line, especially in the vegetable industry. Its hygienic design, durability, and operational flexibility make it an ideal choice for handling a variety of vegetables, ensuring a smooth, efficient, and safe production process.

https://www.dyfoodmachines.com/elevating-conveyor/vege-conveyor/

Mail:deyinmachine@gmail.com Report this page